| NSF certified |

Well suited for industrial, hotel, pharmaceutical, domestic, and food & beverage water softening applications |

Produce Pure Water |

| Salt saving |

Reduction of 20 - 50%in commercial salt quantity required for regeneration |

Reduce operating costs and discharge less chemicals into the environment |

| Water saving |

Saves from 30-50% on risen water and reduction in salt dilution water |

Use less water; 40-80% reduction in volume of waste water and disposal costs |

| Iron removal |

Prevents resin fouling from heavy metals |

Perform fewer change-outs; durable resin resists fouling, osmotic shock and oxidation for extended resin Life |

| High hardness |

Effective for hardness levels in excess of 700 ppm and up to 2,000 ppm |

Reduce maintenance costs and extended equipment life; an economical solution for testing hard water with high TDS |

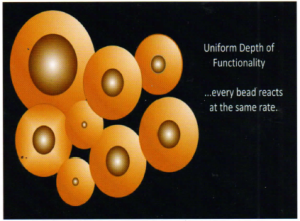

Key Advantages of Shallow Shell™ Technology Resins versus traditional resins

. Significantaly improves echnomics in water softening processes

. Lower leakages at same regenerant dosage compared to traditional resin

. Significant reduction in salt dosage to achieve same leakage

. High capacity and increases throughput for optimal system performance

. Compatible with co-flow, counter-flow and packed bed systems

Suggested Applications for Shalloe Shell™ SSTC60

. Waste water and Zero Liquid Discharge projects

. High TDS / high hardness water softening

. Softening of waters with high iron levels

. Removal of heavy metals and hardness prior to RO systems

. Water - and salt - saving greeen initiatives